Contents

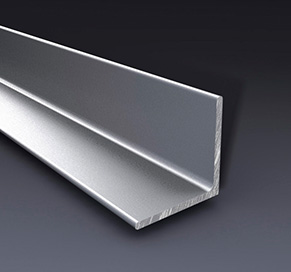

Ninthore Overseas is one of the leading manufacturers of Stainless steel Angles. We understand the need of the clients and serve them with the best quality of stainless steel angles. Our company provides S S Angle with various dimensions, shapes, sizes, thickness and grades.

We provide S S 304 angle, stainless steel 304 L angles, stainless steel 316 angles, SS 316 L angles, S S 316 Ti angle, S S 321 angle, SS 347, stainless steel 309 angles, S S 310 angle, SS 310 S, stainless steel 409 angles, stainless steel 409 M angles, SS 410 angle, S S 410 S angle, S S 420 angle, SS 430 and stainless steel 440 angles. We provide stainless steel pipe angle, S S L type angle, stainless steel T type angle, S S V type angle and stainless steel equal angle bar. Apart from the standard sizes, thickness and dimensions of the S S angle, we provide these metal angles with non standard steel angle sizes and dimensions, as per the requirements and demands of the clients.

Uses of stainless steel angles

Stainless steel angle products have various uses in different fields. S S angle are manufactured from superior quality raw materials. They are tested for their utility in different industrial uses. All angles have their uses in Aerospace industry, Architectural industry, Commercial and Residential Construction industry, Chemical industry, Food Processing industry, Oil and Gas industry, Textile industry, Pharmaceutical industry, Pump shafts and parts in machinery used to process paper, Railways, Heavy engineering industry and Defence industry. Varied sizes, grades, thickness and dimensions makes the angles more flexible to meet the intended uses.

Product Specifications

Ninthore Overseas has mastered in production of good and high quality stainless steel angle. The raw materials used during production process are inspected to meet the quality standards to the international markets. They are cut to the sizes as per the demands of the clients and their intended uses in an industry. SS angles are highly durable and dynamic. These S S angles are corrosion resistant and rust resistant. They have high durability and can last longer as these angles can be recycled. S S Angles posses good strength to weight ratio. They can easily be machined and they are easy to handle. SS angles are non magnetic and are tensile. All angles are carefully coated and packed, so they are damage resistant. Also, S S angles have excellent long term value. Stainless steel angle is processed by hot rolling and cold rolling techniques.

Production process of Stainless Steel

The manufacturing of angles includes a series of process.

- The raw materials such as iron ore, chromium, silicon, nickel, carbon, nitrogen and manganese melts in an electric furnace. It is in semi-finished form.

- The semi finished formed steel undergoes hot rolling. Here the steel undergoes heated and passed through hot huge rolls.

- The stainless steel is put through heat. and cooled down at a prescribed temperature which is known as annealing. This process requires a lot of careful control.

- After annealing a scale is formed on the steel. Descaling can be done through various process. The most common process is pickling. It includes nitric hydrofluoric acid bath. Annealing and descaling can be conducted at different stages depending on the type of steel being worked on.

- These stainless steel then undergoes through cutting and surface finishing.

- The stainless steel are packed and fabricated to the end user.